Description

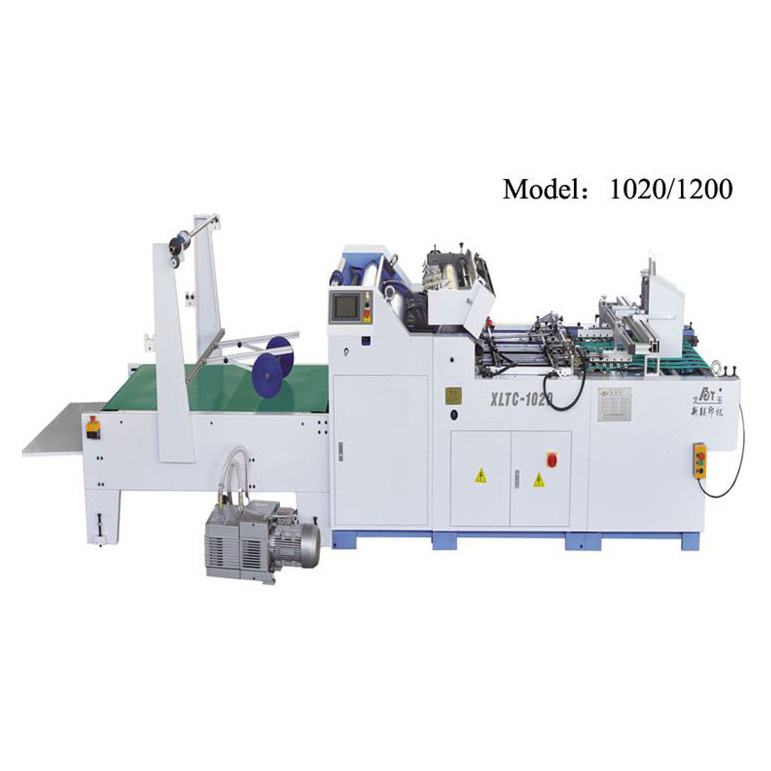

Automatic window patching machine 1020/1200

| Model | XLTC-1020 | XLTC-1200 |

| Max. Paper Size | 1080×630mm | 1200×720mm |

| Min. Paper Size | 140×140mm | 140×140mm |

| Max. Film Size | 410×300mm | 410×300mm |

| Min. Film Size | 80×60mm | 80×60mm |

| Film Thickness | 0.05-0.20mm | 0.05-0.20mm |

| Max. working speed | 8000s/h | 6000s/h |

| Carboard | 200-500g/㎡ | 200-500g/㎡ |

| Corrugated Paper | ≤7mm | ≤7mm |

| Total Power | 9Kw | 10Kw |

| Total Weight | 3000kg | 3500kg |

| Overall Dimensions | 5000×1960×1750mm | 6200×2000×1750mm |

| (When the roller pull out the dimensions) | 5000×3160×1750mm | 6200×3260×1750mm |

General Introduction

XLTC-1020 Window Patching Machine is widely used in the film patching and reinforcement to the package with or without the window of mobile phone box, liquor box, gift box, napkin box, cosmetic box, toy box, milk case and cards. The cardboard is 250-1200g/m2 and also can attached with the sticker punching, die cutting and creasing etc. for the special functions. It can be used for the function of the paper gluing, film patching, film cutting , creasing and clearing function.

The machine has passed the ISO9001 Quality System Certificate and conform the European CE safety standard.

Features by parts

Paper Feeding Part

This machine uses a 7 inch touch screen to digitally adjust the film length, counting, etc.

The paper feeder parts is controller by the servo motor,the paper pile make the intermittent movement in the process of the paper feeding,the belts operate long life ,process the paper products to the conveying parts steady and orderly.

Perfect for the cardboard and corrugated.

Conveying Parts

The paper conveying parts installed the four conveying chains with the four pushing blocks, it can be adjusted according to the paper shape. It is equipped with the 4 photosensor, detect the paper reaching condition, counting, paper jammed detection.

Gluing Parts

The gluing parts adopt the adjustable parts gluing structure, it is convenient for adjustable according to the paper requirement and the gluing position, save the gluing quantity, it is easy for pulling out the gluing parts ,convenient for washing. The gluing roller stopped the gluing when stopped the machine. And the conveying parts dropped automatically, the gluing is not easy to print on the conveyor belts.

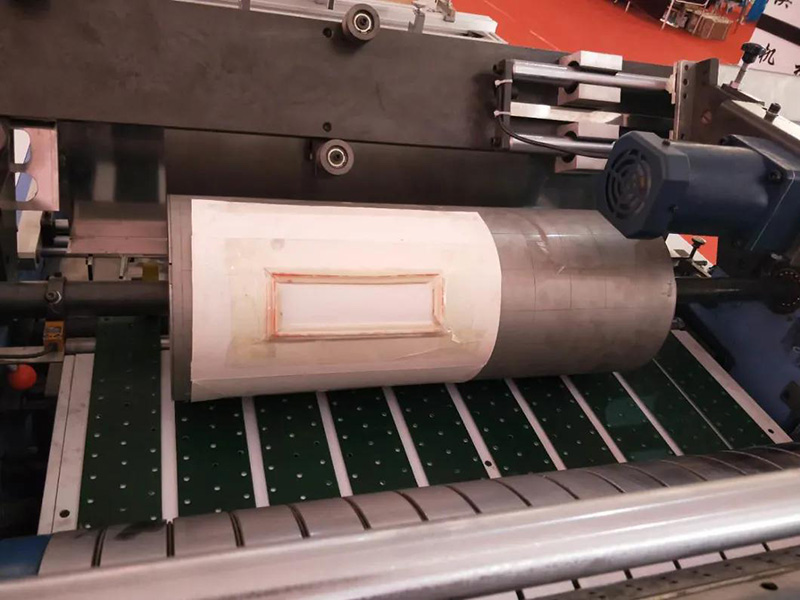

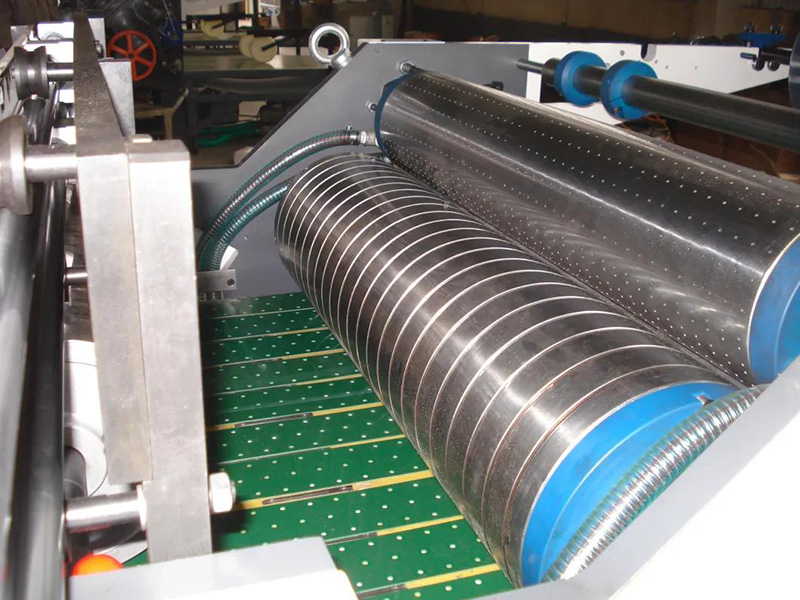

The upper roller is the cutting film roller with the two blade, one the upper blade, the other is the lower blade, finishing the cutting of the film.

The below roller is the suction roller, the film is patched on the suction roller.

Servo film adjustment: easy and convenient to adjust the film, time saving.

Paper Delivery parts

The patching products conveying to the paper delivery plate, finish the paper accumulation and collection.

Paper delivery parts can be adjust separated.

Hot Tags: window patching machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, film, window, pvc, bopp, industrial laminating machine, Automatic Water-Based Film Laminator Machine, Automatic Slitting Machine, Crash Lock Bottom Paper Box making machine, carton stripping die cutting machine, Manual Ab Pieces Folder Gluer Machine.