Good quality Electric Laminator - Auto Flute Laminating Machine – Lianji Detail:

Description

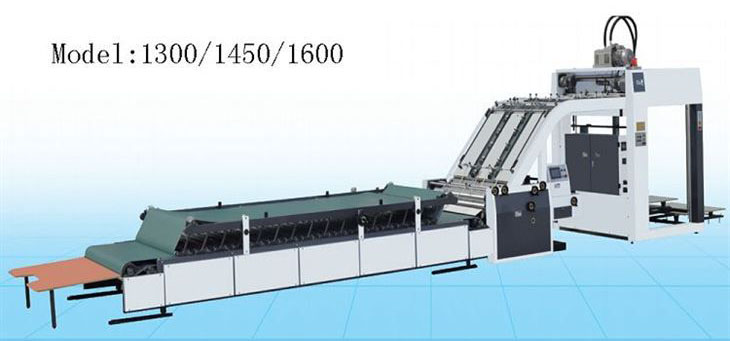

Auto flute laminator 1300/1450/1600

Specifications

| Model | 1300 | 1450 | 1600 |

| Max. Paper Size | 1300*1200mm | 1450*1200mm | 1600*1450mm |

| Min. Paper Size | 360*360mm | 360*360mm | 360*360mm |

| Face paper thickness | 200-450g/㎡ | 200-450g/㎡ | 200-450g/㎡ |

| Bottom paper Thickness | ≤8mm | ≤8mm | ≤8mm |

| Max. working speed | 120m/min | 120m/min | 120m/min |

| Production efficiency | 2000-6000sheets/h | 2000-6000sheets/h | 2000-6000sheets/h |

| Total Power | 12.5Kw | 12.5Kw | 17.5Kw |

| Total Weight | 5800kg | 6500kg | 78000kg |

| Overall Dimensions | 11500*2150*2300 | 11500*2300*2300mm | 12500*2500*2300mm |

Equipment Introduction

ZFM 1300/1450/1600 automatic flute laminator adopts the automatic feeding system of face paper and bottom paper, which is suitable for the high-speed automatic laminating paper of color printed facial paper and corrugated board.

Function Feathers

Adopt front lay positioning technology, accurate positioning, and the bottom paper not exceed.

The face paper conveying adopts feida automatic paper feeding method, and the paper feeding is reliable and stable.

Adjust the relevant parameters according to the paper size, so that the machine runs always in the most ideal state.

The bottom paper conveying adopts the suction belt feeding mechanism, and adopts the retractable paper supporting structure to support paper, which can adapt to the size of corrugated paper.

The pressure roller adopts double-sheet anti-impact structure to protect the accidental damage to the roller.

The pre-coded paper mechanism can stack the next batch of face paper without stopping the machine, which reduces the downtime.

Adopted imported electrical parts, and the electrical system is stable and reliable.

The whole machine adopts PLC, servo system, touch screen control, which is convenient for on-site operation.

Adopts automatic gluing system to improve the degree of automation.

Adopt frequency converter speed regulation system to realize stepless speed change.

FAQ

1. Where is the delivery port?

Tianjin Port, China.

2. Can your company handle shipping for customers?

Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order).

3. Are you manufacturer?

Yes, Our parent company has been engaged in manufacturing for more than 20 years. We are manufacturer with 10-year experience and profession.

Hot Tags: auto flute laminating machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, Jelly Glue Rigid Box Gluing Machine, foil stamping hot press holographic positioning machine, carton waste removing die cutting machine, Feeder die cutting, Flute Corrugated Board Box Laminating Machine, paper lamination machine.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Good quality Electric Laminator - Auto Flute Laminating Machine – Lianji, The product will supply to all over the world, such as: Luxemburg, Nepal, Kuala Lumpur, If you are for any reason unsure which product to select, do not hesitate to contact us and we are going to be delighted to advise and assist you. This way we are going to be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We have been looking for more and more customers to create the glorious future.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

-

OEM/ODM Factory Old Die Cutting Machine - Auto...

-

OEM/ODM Supplier Lamination Machine Laminator -...

-

Reasonable price Carton Gluer Machine - High e...

-

Excellent quality Laminator Lamination Machine ...

-

Fast delivery Bronzing Machine - Cardboard Gas...

-

Hot sale Automatic Case Machine Machine - Card...