Delivery Section

1. Automatic paper collecting is realized.

2. To guarantee the continuous collection, when the paper pile reaches a certain height, the paper plate shall be inserted into the paper pile, and the paper collection can be finished.

3. Side paper and back paper making device ensures that the paper pick-up brush and the paper-collecting flop device avoid paper shake. The position of each device can be adjusted to suit different layouts.

4. Optional Delivery Platform.

According to the requirement of the client we can do the delivery platform either square type or E type (as shown in the picture). If the client has enough pallets, he can choose square type. If the client does have enough pallet, he can choose, E type platform for which will also provide.

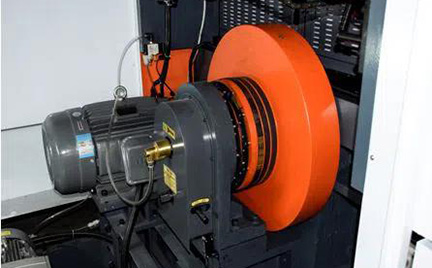

The chase locking is pneumatic method, which is simple, convenient and reliable.

Ingenious and special front row design: Compared with cardboard, corrugated cardboard has greater strength. If the corrugated cardboard reaches the front row abnormally, the front row and the clamping line will be damaged when the front row reaches the highest position.

Generally, producers will install sensors in this part to stop the machine when the paper is fed into the front row abnormally. However, when the machine is running at high speed, the inertia will cause the machine to run for a period of time, so that the front side member reaches the highest point, and then the front side member and the clamp rod will be damaged.

Our special design is that when abnormal paper feeding occurs and is detected, the front row will never reach the highest point, so as to avoid damage to the front row and the paper clamp lever due to abnormal paper feeding.

Hot Tags: platen cutting machine, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, Semi automatic Flute Laminator, cold film laminating machine, automatic die cutting Paper packaging, PE Pet PVC Plastic Film Adhesive machine, Thermal film coating machine, paper grid molding machine.