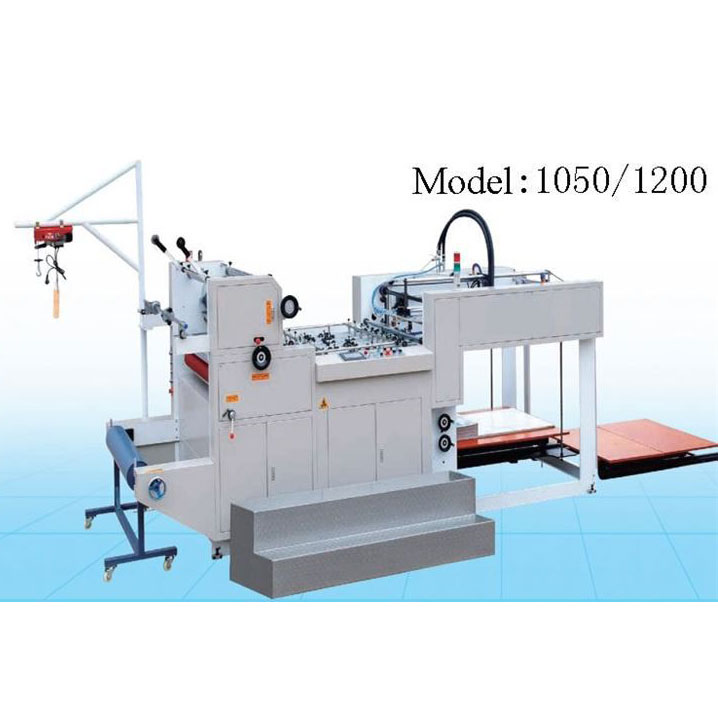

High Quality Water Based Film Laminator - Automatic Water Based Film Laminator – Lianji Detail:

Description

1050/1200 automatic water based film laminator

RCFM serious Specification

| Model | FM-1050 | FM-1200L |

| Max. Paper Size | 1050*1100mm | 1200*1450mm |

| Min. Paper Size | 380*295mm | 400*350mm |

| Paper Thickness | 80-400g/㎡ | 80-400g/㎡ |

| Working speed | 20-110m/min | 20-110m/min |

| Total Power | 7.5Kw | 8.5Kw |

| Total Weight | 3T | 3.8T |

| Overall Dimensions | 4800*1850*1850mm | 5550*2150*1850mm |

| Model | RCFM-1050 | RCFM-1200L |

| Max. Paper Size | 1050*1100mm | 1200*1450mm |

| Min. Paper Size | 380*295mm | 400*350mm |

| Working speed | 20-110m/min | 20-110m/min |

| Total Power | 10Kw | 11Kw |

| Total Weight | 3.5T | 4.3T |

| Overall Dimensions | 5000*1850*1850mm | 5700*2150*1850mm |

| Model | FM-1050 | FM-1200L |

| Max. Paper Size | 1050*1100mm | 1200*1450mm |

| Min. Paper Size | 380*295mm | 400*350mm |

| Paper Thickness | 80-400g/㎡ | 80-400g/㎡ |

| Working speed | 20-110m/min | 20-110m/min |

FM serious function feathers

High-speed feeder, specially designed front lay and pulling lay make the conveyance of coated paper high-speed, stable and accurate.

The paper feeding adopts photoelectric centralized control, automatic stop of empty sheets, automatic filling of empty sheets and other functions, which makes the operation more labor-saving.

The uniquely designed power control system enables the film and paper to be transported separately, making it easier to operate when replacing the paper and film, and directly reducing the scrap rate.

The gluing adopts the international popular gluing method, which makes the amount of gluing more uniform and controllable, effectively reducing the production cost of customers.

The main motor adopts frequency conversion speed regulation, and the electrical components are all internationally renowned brands, and there are almost no electrical faults.

Equipped with a foreign baffle to make the equipment run more safely.

RCFM series function feathers

RCFM automatic water-based (powder removal) film laminator is based on the FM series model and has a new hot-press powder removal function.

The hot-pressing powder removal function effectively reduces the amount of glue used and the film finish is better; at the same time, the hot-pressing residual temperature makes the product dry faster and have a stronger stiffness.

FAQ

1. What is the machine warranty?

One year.

2. Can your company handle shipping for customers?

Yes.(Please provide us your requested seaport and we can check the shipping charge and arrange shipping for your order).

3. Do you have stock product to sell?

Actually our machine need 20-30 days to manufacture, and there are many orders from China and foreign countries, and your order will be highly attention to manufacture.

Hot Tags: automatic water based film laminator, China, manufacturers, suppliers, factory, carton, box, BOPP, corrugated, high speed, Xinlian, made in China, Hot Foil Stamping Die Cutting Machine, corrugated die cutter, flute laminating machine, film laminating coating machine, Gift Box Machine, big size gluer and conveyor.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for High Quality Water Based Film Laminator - Automatic Water Based Film Laminator – Lianji, The product will supply to all over the world, such as: Nigeria, Saudi Arabia, Cape Town, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.