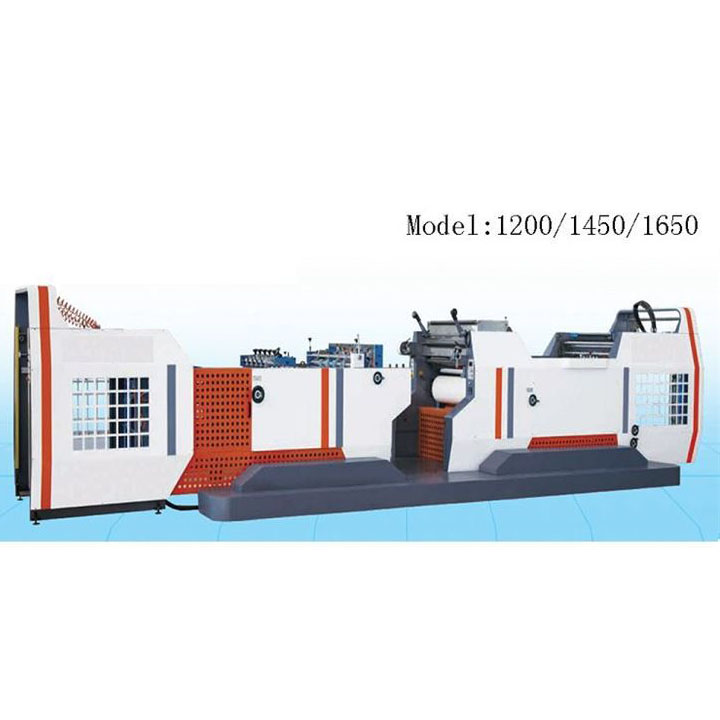

Manufacturer for Double Lanes Film Patcher - High Speed Pre Coating Film Laminator – Lianji Detail:

Description

1100/1450/1650 high speed pre coating film laminator

Specifications

| Model | YFM-1100*1200 | YFM-1100*1450 | YFM-1300*1650 |

| Max. Paper Size | 1100*1200mm | 100*1450mm | 1300*1650mm |

| Min. Paper Size | 400*310mm | 400*310mm | 450*450mm |

| Paper Thickness | 105-500g/㎡ | 105-500g/㎡ | 157-500g/㎡ |

| Working speed | 10-105m/min | 10-105m/min | 10-110m/min |

| Total Power | 34Kw | 36Kw | 38Kw |

| Total Weight | 6200kg | 7200kg | 7500kg |

| Overall Dimensions | 11500*2000*1850 | 12500*2000*1850mm | 12500*3000*1850mm |

According to the needs of customer can increase the chain knife configuration.

Equipment Introduction

YFM series film laminating machine, specialized for pre-coating film, can also use no glue film, one machine dual-use. This machine adopts feeder automatic paper feeding mechanism to attach the paper to the laminating part, and uses a pressing wheel to heat and press the film to attach the film to the surface of the paper. The pressing roller adopts an electromagnetic heating system, which can control the temperature quickly and stably and accurately. The finished product can be in the form of a roll paper or a disc cutter. Both manual delivery and automatic delivery can be choose.

Function Feathers

The feeder is equipped with a pre-loaded paper mechanism, which can realize none stop cycling feeding.

The powder removing machine adopts a hot-pressing electrostatic powder removing mechanism, which presses the sticky powder to preheat the paper at the same time, providing conditions for high-speed working.

The laminating roller of the main machine adopts a new electromagnetic heating system, which can timely compensate the heat taken away by the paper at high speed, and ensure that the isothernal error of the roller is less than 2 °C at high speed.

The laminating roller adopts a gas-liquid supercharger and an 80-diameter hydraulic cylinder, and can be produced normally at 8MPa. The system is durable and does not leak oil.

Equipped with air-expansion shaft and hanging mold mechanism, which is convenient for loading and unloading the membrane.

Film automatic tension control system to ensure the film is smooth and smoothly conveyed.

Optional paper-collecting gas expansion shaft is convenient for customers to choose winding and direct slitting.

The slitter has a thin paper flattening mechanism, which adjusts the flatness of the paper with the tension.

The disc flying knife cooperates with the needle wheel punching device to ensure the reliability of high-speed cutting and cutting.

The take-up machine adopts vacuum adsorption paper feeding, which makes the paper conveying more stable.

Equipped with automatic reversion mechanism, the paper automatically enters the manual paper collection channel when the paper collection is difficult or fails.

Paper-receiving and pressure-increasing structure increases paper stiffness.

The bottom of the paper is equipped with intermittent airflow, which is suitable for thin paper and quick paper receipt.

The take-up machine adopts 4 sets of side-lift and one set of background to ensure that the long strip of paper is neatly received.

FAQ

1. What is your delivery time?

Within 30 days after get the payment.

2. How about after-sales service process?

When your machine has problem, contact your sales and we will solve your problem soon as possible.

3. What’s the payment term?

T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

Hot Tags: high speed pre coating film laminator, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, cold film laminating machine, folding machine in Sheet Folding, Two Cartons Glue Machine, high speed die cutting machine, cutting machine blades, Automatic Book Cover Machine.

Product detail pictures:

Related Product Guide:

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for Manufacturer for Double Lanes Film Patcher - High Speed Pre Coating Film Laminator – Lianji, The product will supply to all over the world, such as: Georgia, Maldives, United Arab emirates, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!