Previously received requests from Greek customers and asked for a folder gluer that can paste express bags.

After continuous research and development, the folder gluer workshop finally developed a new machine.

It adopts a sub-module design, which can increase or decrease modules, could add four or corners unit or strip stick unit.

Faster speed, higher precision, to meet the needs of special products.

The machine is now in production and will be completed soon. We look forward to customer feedback.

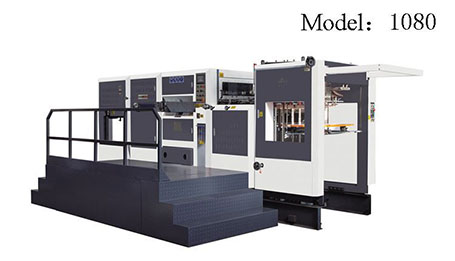

The die-cutting process is the most commonly used process for packaging tape. It uses a die-cutting knife to form a die-cutting plate according to the pattern required by the product design. Under pressure, the tape or other plate blanks are rolled into the desired shape or The forming process of the cut marks. The creasing process is to use a crimping knife or a crimping die to make a line mark on the sheet by pressure, or use a rolling wheel to roll out a line mark on the sheet, so that the sheet can be bent into a predetermined position.

Usually, the die-cutting and creasing process is a process of combining the die-cutting knife and the crimping knife in the same template, and simultaneously performing die-cutting and creasing processing on the die-cutting machine, which is called die-cutting for short.

The main process of die-cutting is: loading the plate → adjusting the pressure → determining the distance → sticking the rubber strip → pressure test die cutting → formal die cutting forming → waste removal → finished product inspection → point packaging.

Last edition

First of all, proofread the finished die-cut version, and roughly observe whether it meets the requirements of the design draft. Whether the position of the steel wire (crimping knife) and the steel knife (die cutting knife) are accurate; whether the cutting line for slotting and opening is a whole line, and whether the line turning is at a round corner; in order to facilitate cleaning, adjacent narrow waste edges Whether the connection enlarges the connecting part so that it is connected together; whether there is a sharp corner at the joint of the two lines; whether there is a situation where the sharp corner line ends in the middle paragraph of the other straight line, and so on. Once the above problems occur in the die-cutting plate, the plate maker should be notified immediately to make corrections to avoid more time waste. Then, install and fix the produced die-cutting plate in the plate frame of the die-cutting machine, and adjust the position of the plate initially.

Adjust pressure, determine rules and stick rubber bullets

To adjust the layout pressure, first adjust the pressure of the steel knife. After the paper is loaded, start to press several times so that the steel knife is flattened, and then use a cardboard larger than the die-cutting layout to test the pressure. According to the cut marks cut by the steel knife on the cardboard, use partial or full incremental pressure or the method of reducing the number of lining paper layers makes the pressure of each knife line of the layout reach uniformity.

Post time: Aug-25-2022