Description

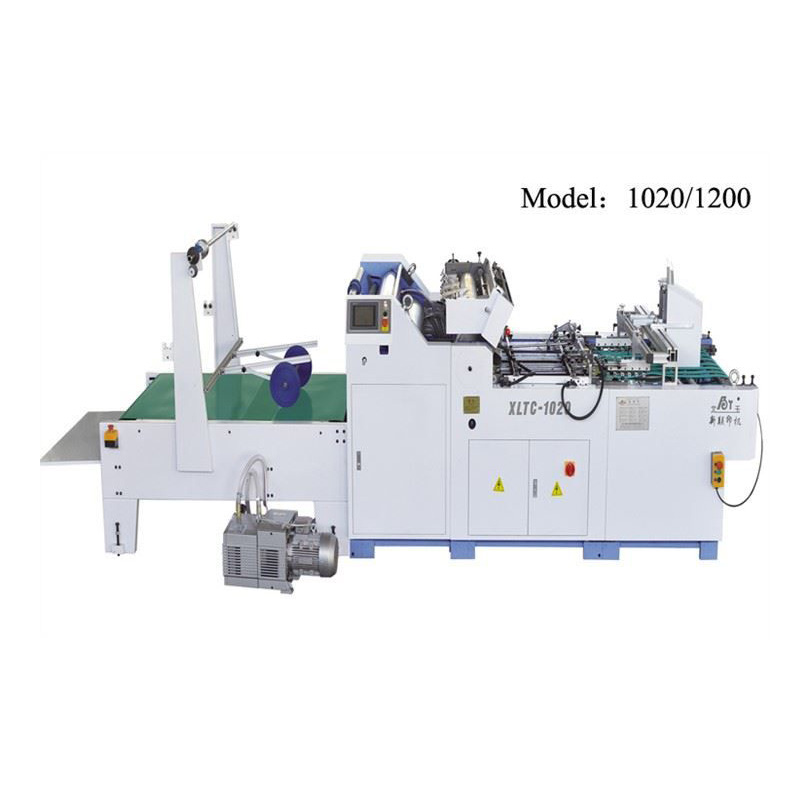

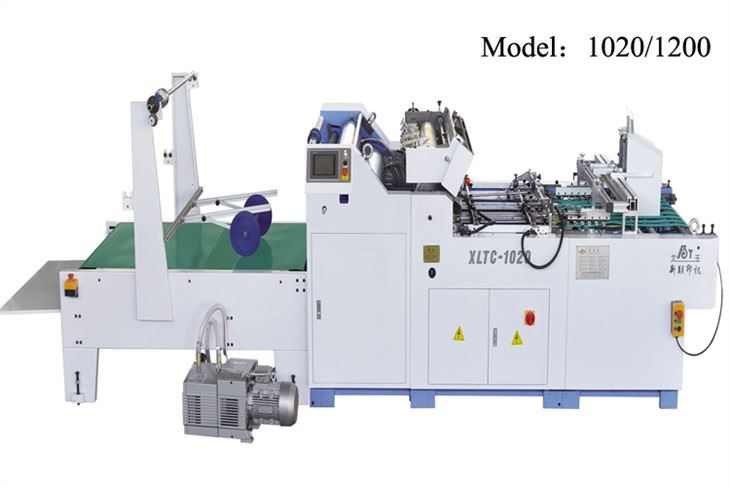

Automatic window patching machine 1020/1200

| Model | XLTC-1020 | XLTC-1200 |

| Max. Paper Size | 1080×630mm | 1200×720mm |

| Min. Paper Size | 140×140mm | 140×140mm |

| Max. Film Size | 410×300mm | 410×300mm |

| Min. Film Size | 80×60mm | 80×60mm |

| Film Thickness | 0.05-0.20mm | 0.05-0.20mm |

| Max. working speed | 8000s/h | 6000s/h |

| Carboard | 200-500g/㎡ | 200-500g/㎡ |

| Corrugated Paper | ≤7mm | ≤7mm |

| Total Power | 9Kw | 10Kw |

| Total Weight | 3000kg | 3500kg |

| Overall Dimensions | 5000×1960×1750mm | 6200×2000×1750mm |

| (When the roller pull out the dimensions) | 5000×3160×1750mm | 6200×3260×1750mm |

General Introduction

XLTC-1020 Window Patching Machine is widely used in the film patching and reinforcement to the package with or without the window of mobile phone box, liquor box, gift box, napkin box, cosmetic box, toy box, milk case and cards. The cardboard is 250-1200g/m2 and also can attached with the sticker punching, die cutting and creasing etc. For the special functions. It can be used for the function of the paper gluing, film patching, film cutting, creasing and clearing function.

The machine has passed the ISO9001 Quality System Certificate and conform the European CE safety standard.

Main feature

1. The linear structure is simple and easy to install and maintain.

2. Pneumatic part, electrical part and operation part all adopt advanced world-renowned brand components.

3. The high pressure double crank controls the mold opening and closing.

4. The operation is automated, with a high degree of intelligence and no pollution.

5. Use the connector to connect with the air conveyor, which can be directly connected to the filling machine in series.

Hot Tags: window patcher for packaging box, China, manufacturers, suppliers, factory, price, carton, box, automatic, corrugated, high speed, Xinlian, made in China, flat bed For packaging box, plastic packing Servo type, cutting machine blades, assembling box, sheet to sheet Cardboard, inner laminating machine.